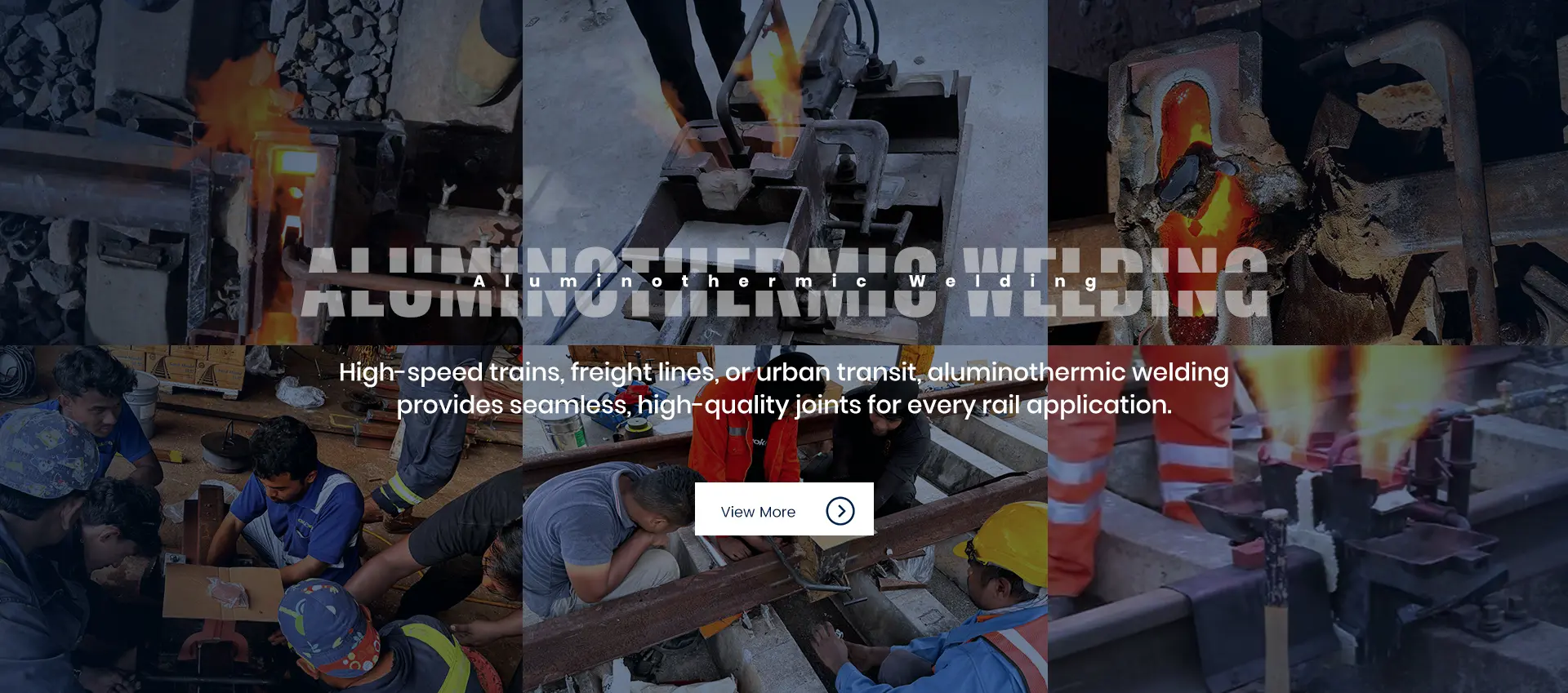

Evolution of Aluminum Thermite Welding: A Historical Perspective

Aluminum thermite welding, also known as aluminothermic welding or thermit welding, is a specialized welding technique that utilizes a chemical reaction to generate intense heat for joining aluminum components. This article aims to explore the development and evolution of aluminum thermite welding, highlighting key milestones and advancements in this field.

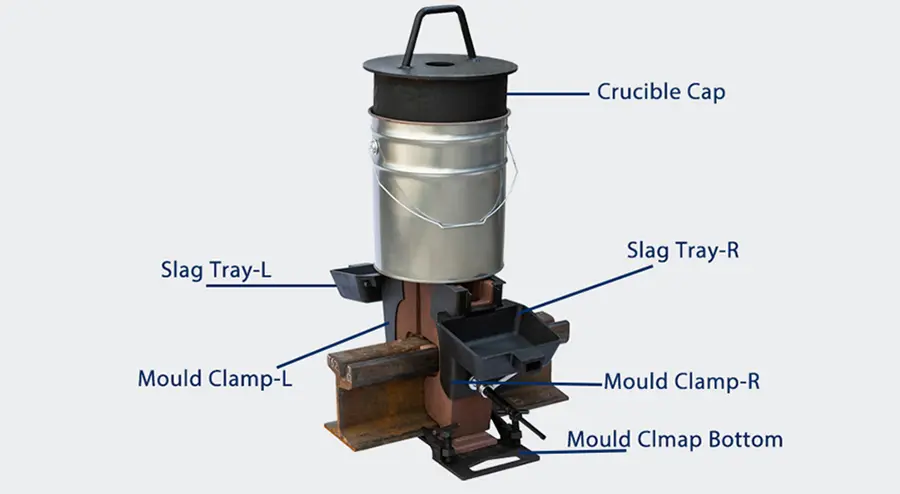

Thermit Welding process

Stp.1 Ensure the rail ends to be welded are clean, free from rust, and properly aligned. The gap size (space between two rails to be welded)shall be 26±2mm.

Welding instructions

Thermit welding materials will be failed with water. All welding materials should be kept away from any moisture in storage, as well as in the welding process.

Storage Instruction

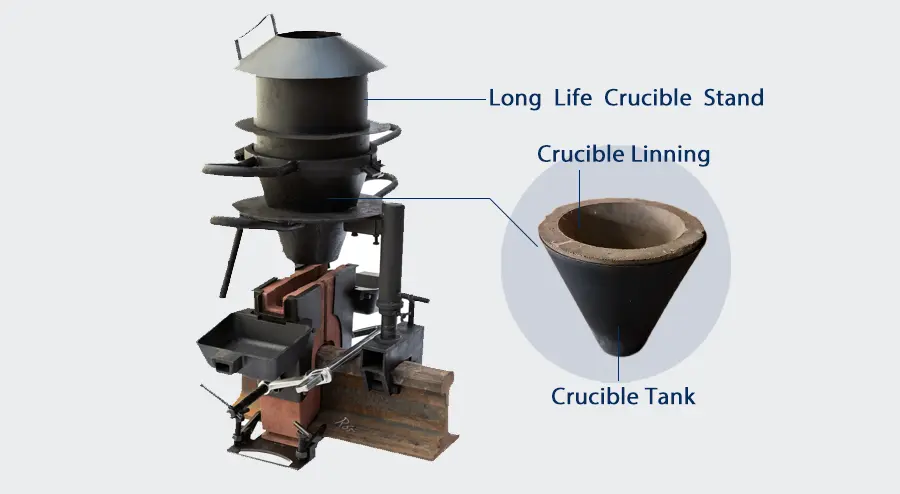

Thermit welding, also known as aluminothermic welding, requires careful handling and storage of its materials to ensure safety and optimal performance.

0102030405

-

since1995Thermit welding R&D

-

5500㎡Production Area

-

5Research Patents

-

15+Exported Countries

-

780+Rail Application Case